(1) Solid board: as the name implies, solid board is made of complete wood. Advantages: strong and durable, with natural charm lines, is the most natural furniture plate inside the environmental protection. It is the best choice for home decoration. Disadvantages: plate cost is high, strict requirements for the process, master is not easy to deformation, cracking problem is almost unavoidable, fire performance is relatively not ideal, so the use of decoration is not much. Solid board is classified according to plank substance name commonly, do not have unified standard specification. Different tree species have different wood hardness and so on. Because real board is more and more exigent, cost is higher and higher, because this is more nowadays to make high-grade furniture development, because can be carved directly on plank all sorts of flower, design is very much used to make classic style furniture.

(2) plywood (plywood, fine core board) : the log after steaming, boiling softening, along the direction of the growth ring cut into thin wood, after adding glue with three layers or more than three odd veneer, crisscross gluing, hot pressing. Advantage: the surface is natural and beautiful, retain the beautiful decorative pattern of natural wood, when using, need not glue to stick other material to stick a face commonly, should use coating to undertake besmear to act the role of hind can obtain excellent appearance only. Good strength and toughness, strong nail holding force, easy to process, insulation, and can make up for some natural wood defects, such as: small size, deformation, vertical and horizontal mechanical differences. The furniture is lighter than other wood-based panels. Good bending resistance.Weakness: The integral material that uses to do furniture less so, use at furniture commonly act the role of facial bit. According to different thickness specifications, plywood is generally divided into 3 per cent, 5 per cent, 9 per cent, 12 per cent, 15 per cent and 18 per cent board six specifications. Because plywood has be out of shape small, size is big, construction is convenient, not warping, horizontal grain resist pull force to learn the advantage such as performance is good. Therefore, this product is mainly used in furniture manufacturing, interior decoration, residential construction of various plates, followed by shipbuilding, car manufacturing, various military, light industrial products and packaging and other industrial sectors.

(3) joinery board (large core board) : the middle is a natural wood bonding core, sticky on both sides of the very thin veneer, so also known as large core board, is one of the most important materials in the decoration. The price of big core board is cheaper than fine core board, that is, plywood that is said above. It has small density, small deformation, high strength and good dimensional stability, so it is widely used. There are poplar, tung, Chinese fir, white pine and so on commonly. High quality products are smooth, without degumming, sand damage, indentation, thickness deviation is small, no obvious hollow core after sawing. Advantages: solid quality, sound absorption, heat insulation. Outside a few that say besides above, as a result of its processing technology is simple, hold nail ability is good, because this is decorating a company spot to hit furniture very welcome. Disadvantages: affected by processing technology, according to the core material to distinguish, its vertical bending resistance is poor, transverse is better. In addition, high water content; Formaldehyde content is also higher, need to be treated before safe use. Be afraid of damp, avoid to use in kitchen in construction. A lot of consumers choose big core board, see weight, 2 see price. Actually heavier big core board its quality is worse. Because of its heavy weight, it indicates the use of miscellaneous wood.

From the current overall household furniture industry, the commonly used board is particleboard, density board (medium density board). A detailed dissection of these two materials will therefore be emphasized.

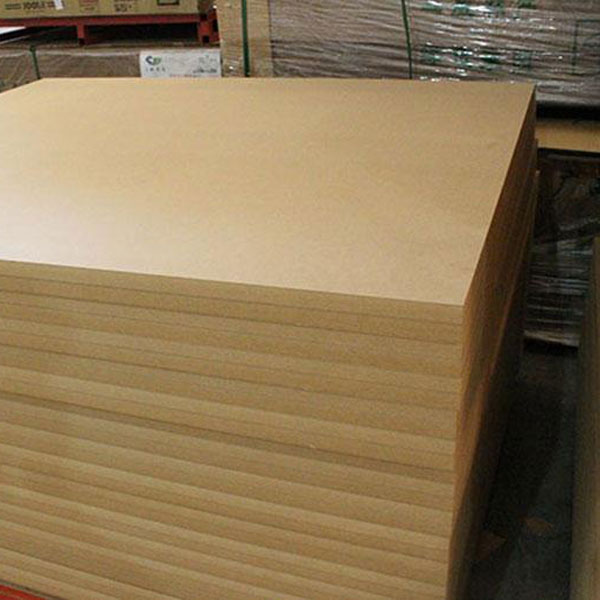

(4) Density board (fiberboard) : is the wood or non-wood plant fiber processing (after cutting, foaming, pulping) into the use of adhesives after high temperature, high pressure made of artificial board. As the name implies: the density is higher than the general plate, according to its density is divided into: high density board, medium density board, low density board. Medium density board is commonly used. Advantages: excellent weak performance, uniform material, no dehydration problem. The performance of MDF is similar to that of natural wood, but without the defects of natural wood. The internal structure is not easy to warpage, cracking, small deformation, suitable for all kinds of mechanical processing. The surface is smooth, the material is fine, the edge is firm, easy to shape, avoid decay, moth and other problems. High bending strength and impact strength. Density board can be carved and other special-shaped modeling. Disadvantages: its disadvantages and its advantages as obvious, moisture resistance, poor grip ability, not easy to fix again. In terms of moisture resistance, if a MDF is immersed in water, it will expand like bread. But pay attention to the expansion too fast or too slow is not good, is likely to be high density board and low density board (these two kinds of plate due to obvious defects now and less use). High processing accuracy and technological requirements, high cost; Because its density is high, because this must use precision saw to cut, unfavorable be in decorate spot processing. In foreign countries, density board production of furniture is a good material, but because of our standard on density board is several times lower than the international standard, so the quality of density board in China still needs to be improved. China’s commonly used density board has 3, 5, 9, 12, 15, 18, 25 per cent several specifications.It’s widely use in cabinets.

Particleboard (particle board) : is used in the process of wood cutting and processing waste or other plant shavings, adding rubber or other auxiliary materials pressed into the board. According to the pressing method can be divided into extruded particleboard, flat pressed particleboard two categories. Advantages: good sound absorption and sound insulation performance. It can be used as sound absorbing building parts such as sound insulation panels and doors. The expansion rate of the board is low and the thickness error of the board is small. Abundant raw materials, low cost, good quality strength, easy cutting processing. It is one of the main materials of ambry box body. The cost is cheaper than medium density board, and the formaldehyde content is much lower than large core board. It is one of the most environmentally friendly man-made panels. Faults: Slightly poor nail grip. The quality difference between different products is large and difficult to distinguish; Poor bending resistance and tensile resistance; Low density easy to loose. Do not make commonly so larger or the furniture that learns forcefully to ask. It is inferior to medium density board in shape. Particleboard specifications are more, thickness from 1.6 to 75 mm, with 19 mm as the standard thickness, commonly used thickness of 13, 16, 19 mm 3. Now, of course, many specifications can be customized. It’s widely use in coffee table, end table, computer tables that in our daily.

Post time: Dec-01-2021